GHG System Case

Case specifically for use with the Figaro NGM2611-E13, Adafruit DHT22, AtlasScientific EZO-CO2 sensor, and 6 D cell batteries. Which informs the sensor plate, cable glands, and power supply (length of case and nylon bar).

[TODO: If we removed / generalized the sensor plate and cable glands requirements / instructions this could generally be for a 12” elongated case]: #

Bill of Materials and Potential Supplier or Drawing

| Item | Case Qty | Buy Qty | Supplier Part # / CAD link |

|---|---|---|---|

| 3” ABS Schedule 40 Pipe | 12” | 10’ | Menards 6881155 |

| 3” ABS Hub x Hub Coupler | 2 | 1 | Menards 6881537 |

| -341 EPDM 70A O-ring | 2 | 15 | McMaster-Carr 9557K316 |

| 18-8 Stainless Steel Threaded Rod 3/8” -16 | 6 | 2’ | McMaster-Carr 98804A031 |

| 18-8 Stainless Steel Hex Nuts 3/8” -16 | 24 | 100 | McMaster-Carr 91845A031 |

| 18-8 Stainless Steel Washers 3/8” | 24 | 100 | McMaster-Carr 92141A031 |

| 5” Copper Mesh/Gauze | 20” | 100’ | McMaster-Carr 6361T16 |

| Dow Corning 111 Molykote | Consumable | 5.3 Fl oz | McMaster-Carr 1204K32 |

| Dessicant Packet | 1 | 1000 | McMaster-Carr 2189K34 |

| 11” Cable Ties | 4 | 100 | McMaster-Carr 7130K55 |

| Dome Cap Cable Gland 1/2” NPT .19-.35” w/ O-Ring & Locknut | 2 | 1 | elecDirect RDC13NR |

| 3/4” wide Velcro | 1” | 5’ | McMaster-Carr 9273K13-9273K133 |

| 18-8 Stainless Steel Phillips Flat Head #6 x 1/2” Screws | 6 | 100 | McMaster-Carr 90065A148 |

| 3/4” x 3/4” Nylon Bar | 1’ | 1’ | McMaster-Carr 8732K17 |

| 1/4” Clear Acrylic Lid Plate* | 1 | NA | CAD Drawing 3inch |

| 1/4” Clear Acrylic Sensor Plate* | 1 | NA | CAD Drawing 3inch |

| 1/4” Clear Acrylic Cage Plate* | 1 | NA | CAD Drawing 3inch |

| ABS Cement | Consumable | NA | Menards 6932185 |

| 2D cell battery holder with center mounting points | 3 | 1 | MPJA 36651 BH |

Diagrams

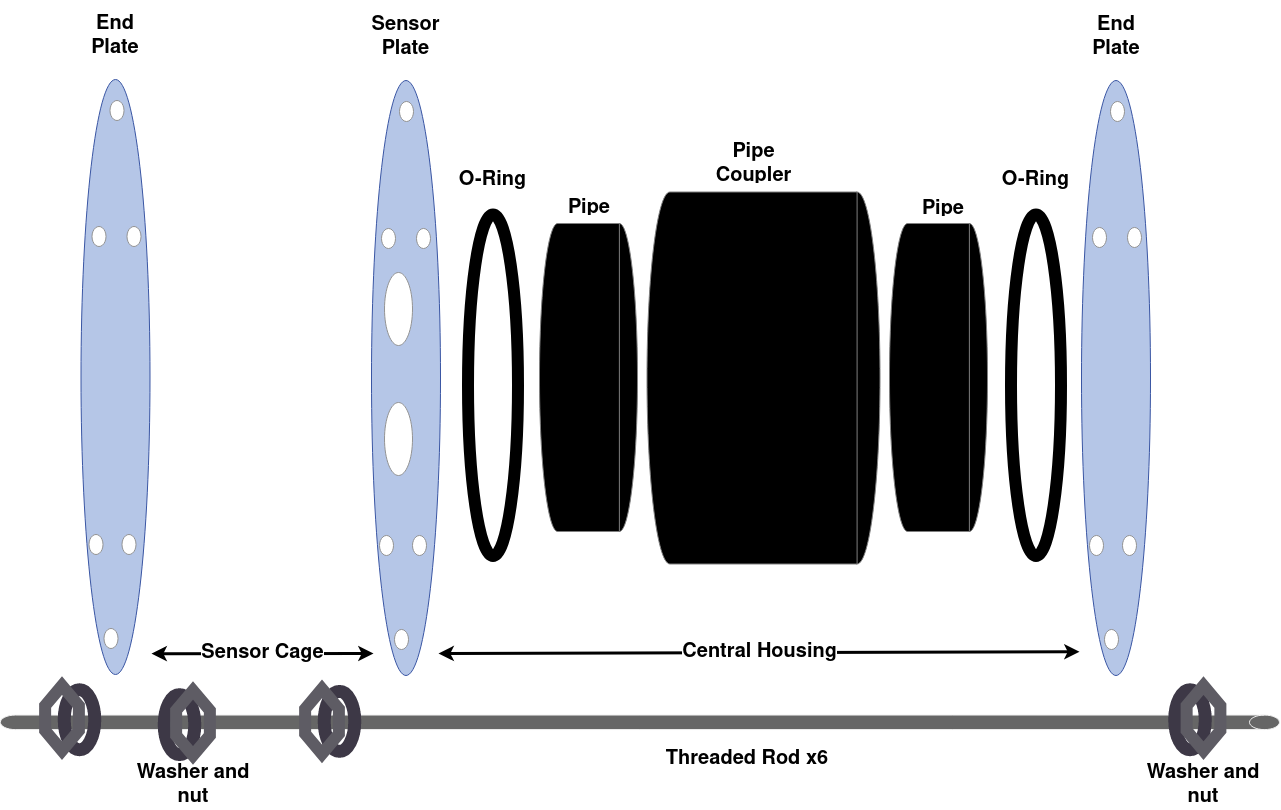

Fig. 1 : Annotated Case Diagram

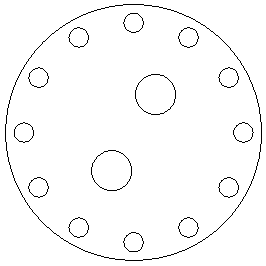

Fig. 2 : Sensor Panel

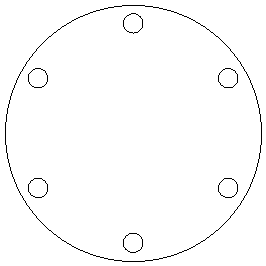

Fig. 3 : Back and Cage Panel

Build Process

Tools & Skills

Fabrication

- Reed TC4QP Tubing Cutter for plastic pipe to cut ABS to length

- Measuring tape

- #2 phillips head screw driver

- Power drill and 1/4” drill bit

Assembly

- 2x 9/16 SAE combination wrench for hex nuts

- Milwaukee 6in Diagonal Cutting Pliers for copper mesh and cable ties

Parts Fabrication

- Cut two 1-21/32” length sections of ABS and 1x 8-1/4” length for the hub inserts and main housing section. When making hub inserts, 20/32 to 22/32 is acceptable, too little won’t hold the o-ring in place, too much won’t compress the o-ring enough to seal properly.

- these lengths may vary depending on brand of coupler, length to cut the ABS sections the O-rings will go around are based on compressing the O-ring around 25% of it’s width of 0.21” = 0.1575” or ~5/32”

- for the NIBCO brand coupler we found a depth of 1 1/2”, so 1 1/2” + 5/32” = 1 21/32”

- we also found the center barrier in the coupler is measured at around 1/4”, 1 21/32” + 1/4 = 1 29/32”, 12” - 2x 1 29/32” = ~8 1/4”

- Mark placement of battery holder screw placements on Nylon bar

- Drill 3/32” pilot holes into nylon bar (for #6 screws) according to battery holder placement centered on bar, then screw battery holder into nylon bar

- Cut 20” of copper mesh

Assembly & Waterproofing

- Attach cable glands

- Apply a small amount of molycote to O-Ring on each cable gland

- Fit cable glands through their respective holes in acrylic sensor plate

- Tighten plastic nut on cable gland gently but firmly to ensure waterproof seal

- Assemble main sonde housing (ABS or PVC)

- Assemble O-Ring ledge

- Find 2 3” pipe D-couplers and 2 1-21/32” sections of 3” pipe

- Apply plastic cement primer to one end of each D-coupler and one end of each pipe section

- Apply plastic cement to primed end of D-coupler.

- Insert primed end of each pipe section into primed and cemented end of each D-coupler

- Tap with rubber mallet to ensure complete insertion, and visually check that that there is no gab between the 1-21/32” pipe section and the insertion ridge inside the D-coupler. This is essential to ensure the correct ledge height for the O-Ring.

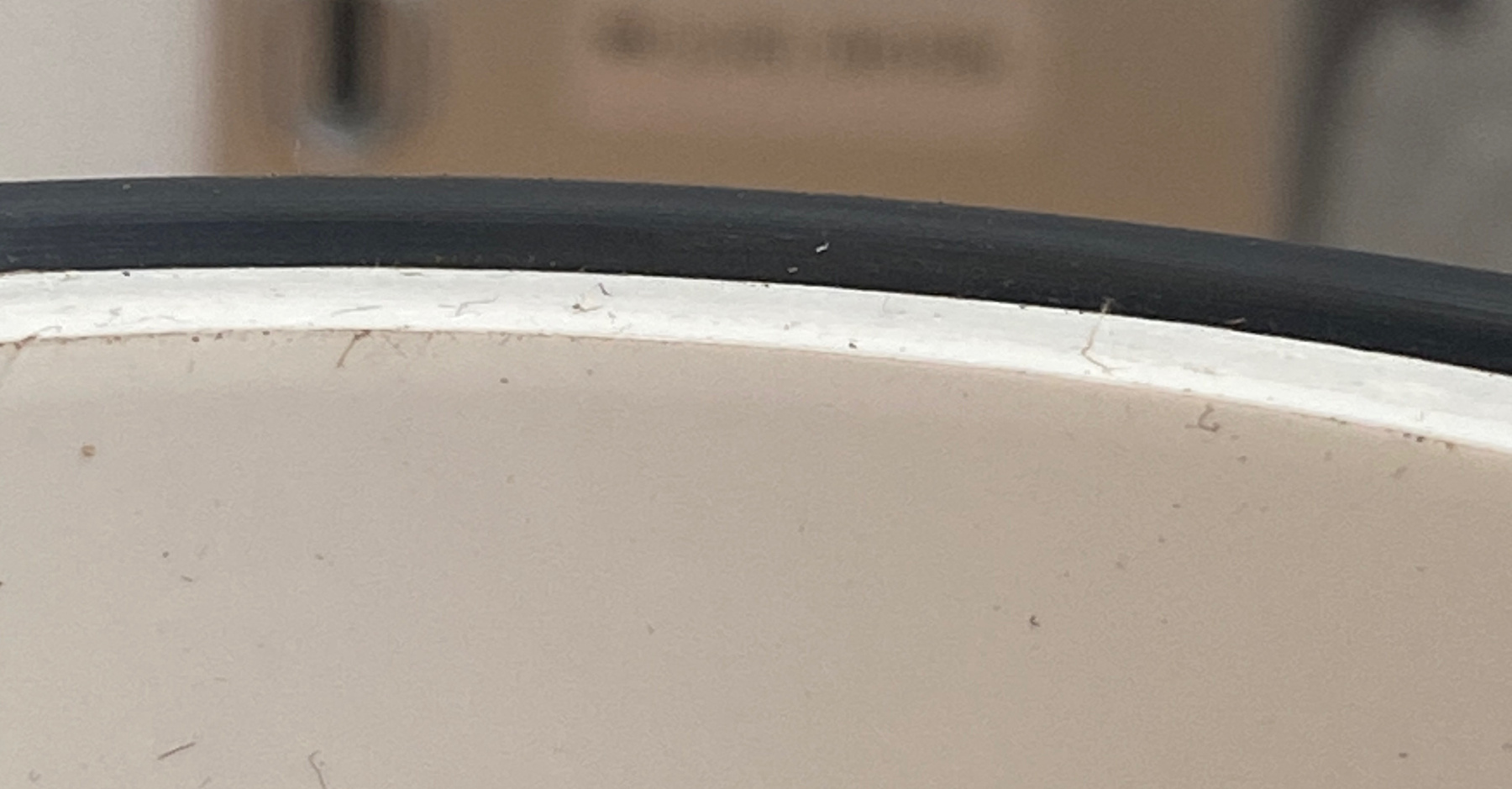

- Check O-ring ledge assembly for correct height.

- Place an O-ring on the ledge created by the inner pipe inserted into the D-coupler in the above steps

- Check that at least 1.5mm of relief exists between the O-ring and the inner pipe segment for the entire circumference of the O-ring.

- The typical reason for a defect at this stage is incomplete insertion of the inner pipe segment into the D-coupler, which can easily compromise waterproofing.

- Correct assembly results:

- Assemble housing body

- Find 2ft length of 3” pipe and 2 O-Ring ledge assembles from (i)

- Check O-ring ledge assembly for correct height

- Checking for a good seal on each O

- Apply plastic cement primer to open end of D-coupler on O-Ring ledge assembly and both ends of 2 ft pipe.

- Apply plastic cement to open and primed end of O-Ring ledge assembly

- Firmly insert primed 3” pipe ends into primed and cemented ends of the D-coupler on each O-Ring ledge assembly.

- Let cure for 3 hours

- Assemble O-Ring ledge

- Build case

- Find 6 threaded steel rods, 24 bolts, 24 washers, 2 O-rings, one sensor plate with cable glands attached, and 2 cage/back plates, and the housing body assembled in (2)

- Build starts from the cage side of the sonde case and proceeds to the back.

- For each hole in the cage plate, sandwich the plate between two washers and two nuts screwed onto the end of a threaded steel rod.

- Screw a nut about 1 inch onto the rod

- Slide a washer up to the nut

- Slide the cage plate onto the rod

- Slide a washer up to the cage plate

- Tighten a 2nd nut up to the cage plate.

- Repeat for each hole in the cage plate.

- Result looks like this:

- Next, use nuts and washers to create a ledge for the sensor plate to rest on.

- Stand the housing from (2) upright, and turn the assembly from (iii) upside down and place on top of the housing. The cage plate will be facing upward.

- Mark each steel rod, using a marker or masking tape, 1 inch paste the height of the housing. This will be the location of the ledge.

- Take the assembly from (2) back off the housing and place cage plate side down on the table.

- Screw a nut onto each threaded rod up to the point that has been marked

- Place a washer on top of each nut

- Place the sensor plate onto the six rods and allow to rest on the 6 nuts and washers there just installed.

- Visually inspect that the sensor plate is reasonably flat and all six washers are at the same level.

- Now, place O-rings and attach the back plate

- Place an O-ring on the O-ring ledge of one side of the housing from (2)

- Apply a thin layer of molykote to the entire surface of the O-ring

- Place the housing on the sensor plate and between the six rods, with the side with the installed O-ring facing down.

- Place a second O-ring on the O-ring ledge on the other side of the housing

- Apply a thin layer of molykote to the entire surface of the second O-ring

- Place the back plate onto the six rods

- Install a nut and washer onto each rod, and firmly screen them down onto the back plate.

- Check that all six sensor plate nuts are tight, and all six back plate nuts remain tight. Tighten any nuts that appear to be loose.

- Visually inspect O-rings for any signs of improper compression

- Over-tightening: O-ring can squish out of place

- Under-tightening: O-ring is not in contact with acrylic plate in some location

- Attach sensors (This step can also happen before step 5 with some experience doing assembly)

- Disassemble sonde case by removing the back panel, then the housing, then the sensor plate.

- Apply a thin layer of molykote to the inside of the cable glands

- Thread sensor cables (without connectors attached) through the cable glands

- Tighten cable glands to provide waterproof seal

- Reassemble sensor place, housing, and back plate onto the 6 steel rods as in (5)

- Assembly can now be dunk tested for waterproofness

- Internal Assembly

- Ensure sonde case is disassembled

- Cut a 1” section of velcro.

- Attach velcro to back of RRIV datalogger PCA and open area on plastic rod

- Plug battery plug into RRIV datalogger

- Assemble sensor connectors

- Place batter/datalogger assembly upright on top of sensor plate.

- Plug sensors into datalogger

- Reassemble sonde case

- Copper mesh

- Wrap copper mesh around sensor cage

- Secure copy mesh to sensor cage using zip ties